5 Questions to Ask Before Ordering Custom Parts

Ordering custom parts can be exciting—but it can also be overwhelming if you’re unsure what information your manufacturer needs. Before you hit “order,” make sure you’re asking the questions that save time, money, and headaches.

Why These Questions Matter

Asking the right questions upfront helps you avoid delays, redesigns, and unexpected costs. Whether you’re prototyping a new product or producing a small batch of functional components, these five questions will set you up for success.

1. What Tolerances Does Your Design Actually Require?

Tolerances are one of the biggest drivers of cost and complexity. Many designs default to unnecessarily tight tolerances, which can:

Increase production time

Limit material options

Require additional post-processing

If a dimension isn’t critical, loosening the tolerance can save time and money. A good manufacturing partner—like the team behind our printing and design services—will help you determine what’s realistic and what’s essential.

In short, only tighten tolerances where they truly matter—it saves time, cost, and complexity.

2. What Material Properties Do You Need?

Material selection affects everything from strength to heat resistance to flexibility. Before ordering, consider:

Will the part experience mechanical stress?

Does it need to withstand high temperatures?

Will it be exposed to chemicals or UV light?

Is weight reduction a priority?

Choosing the right material ensures your part performs as intended. If you’re unsure which material fits your application, our Get a Free Quote form lets you share details so we can recommend the best option.

One project illustrates this well: We worked on a simple bird feeder design—a lower tray for seed with a small awning to keep the food dry. The project originally specified PLA, but PLA has no UV resistance. In direct summer sun, the feeder would have warped within weeks. After reviewing the intended use, we went with UV-resistant ABS instead. The final part has been outdoors for over a year and is still holding up beautifully.

Choosing the right material upfront ensures your part performs reliably in real‑world conditions.

3. How Will the Part Be Used?

Context matters. A part that looks perfect on a screen may fail in real-world conditions if the manufacturer doesn’t understand its purpose. Think about:

Load direction

Assembly method

Environmental conditions

Wear points

Sharing this information helps your manufacturer make informed recommendations. You can also browse our Projects page to see how we’ve solved similar challenges for other customers.

The more context you share, the better your manufacturer can optimize the design for durability and function.

4. What’s Your Timeline?

Lead times vary depending on complexity, material, and finishing requirements. Be clear about:

Your ideal delivery date

Your absolute deadline

Whether you’re open to material or design adjustments to speed things up

Early communication prevents last-minute surprises. If you’re working on a tight schedule, reach out through our Contact page so we can help you plan effectively.

Clear timelines help your manufacturer plan effectively and keep your project on schedule.

5. What Post-Processing or Finishing Do You Need?

Finishing can dramatically change the look and performance of a part. Options may include:

Sanding or smoothing

Painting or dyeing

Machining critical surfaces

Adding threaded inserts

Coating for durability

Each step adds time and cost, so it’s important to plan ahead. If you’re unsure which finishing process your part needs, we can walk you through the options based on your project.

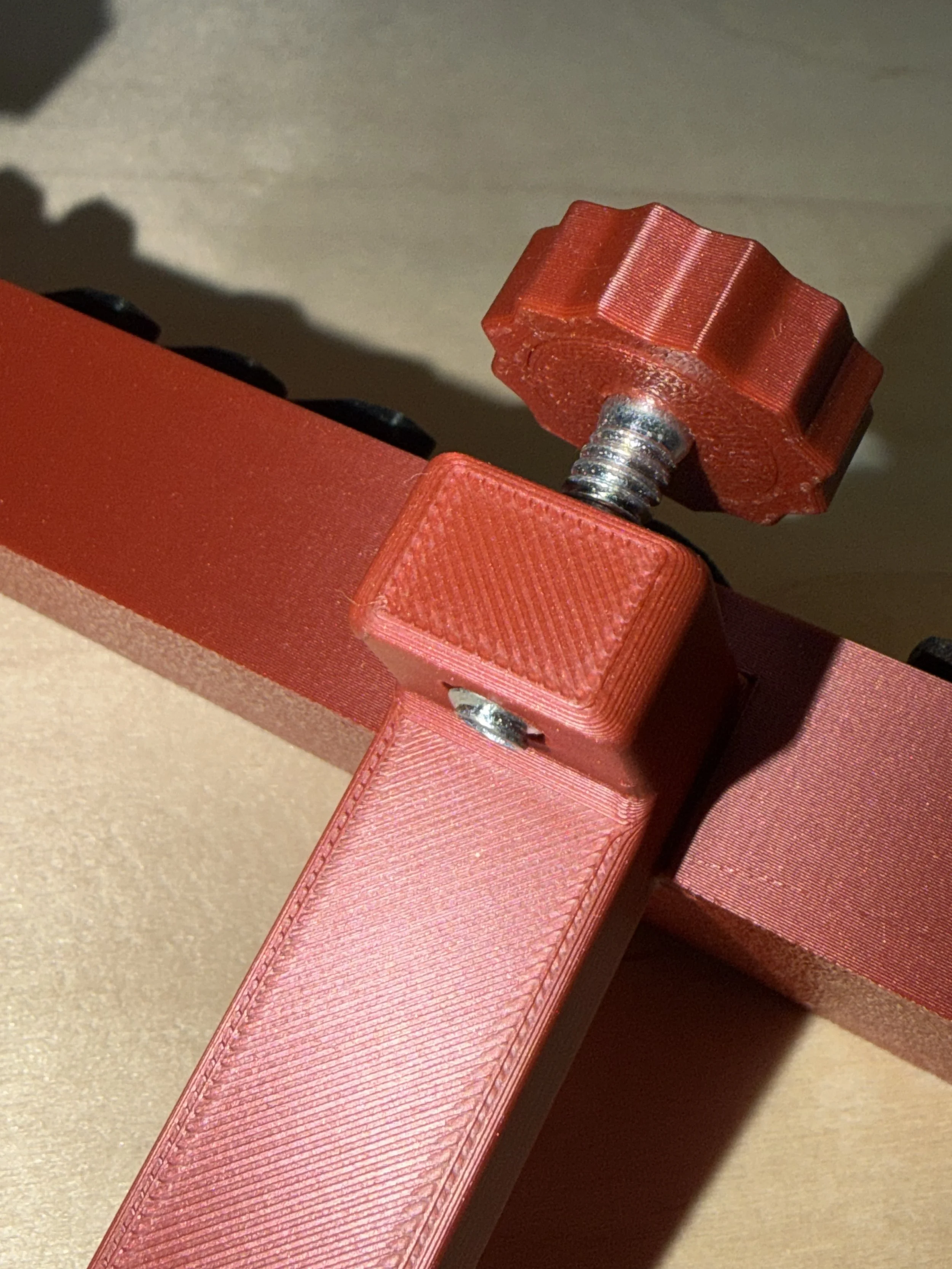

When we designed our Pro‑Series Premium Honeycomb Laser Pins Holder, we wanted a rail‑mounted solution that kept our fire‑resistant hold‑down pins accessible during engraving. The holder needed multiple components to attach securely, and relying on a drilled hole or a self‑tapped screw would have weakened the part over time. Instead, we embedded a threaded insert during the print itself. This gave the holder a strong, reusable fastening point and eliminated the need for extra post‑processing—a perfect example of how the right finishing choice can dramatically improve durability and user experience.

Planning your finishing needs early prevents delays and ensures your part looks and performs exactly as intended.

We reinforced our Pro‑Series Premium Honeycomb Laser Pins Holder by installing a threaded insert during printing, creating a secure, professional‑grade fastening point built for everyday use.

Bonus: Do You Have a Clean CAD File?

A well-prepared file reduces errors and speeds up production. If you’re unsure, your manufacturer can help review or repair your model.

Key Takeaways

Asking these questions before ordering custom parts ensures a smoother process, fewer surprises, and better-performing results. Clear communication upfront helps your manufacturer understand exactly what you need, from material selection to finishing details. At MBS 3D Solutions, we work closely with customers to clarify requirements, optimize designs, and deliver parts built for real‑world use.

Ready to Start?

If you’d like help reviewing your design or choosing materials, you can upload your file through our Get a Free Quote form—we’ll take it from there.