How to Choose the Right Manufacturing Partner for Low‑Volume Production

When you’re producing parts in low volumes, choosing the right manufacturing partner can make or break your project. Low-volume production sits in a unique space: too complex for hobby-level services, too small for traditional mass‑manufacturing workflows, and too time‑sensitive for suppliers who treat small batches as an afterthought. The right partner can shorten development cycles, reduce costs, and help you avoid design pitfalls long before they become expensive problems.

Here’s what to look for when evaluating a manufacturing partner for low-volume work.

1. Engineering Support Matters More Than You Think

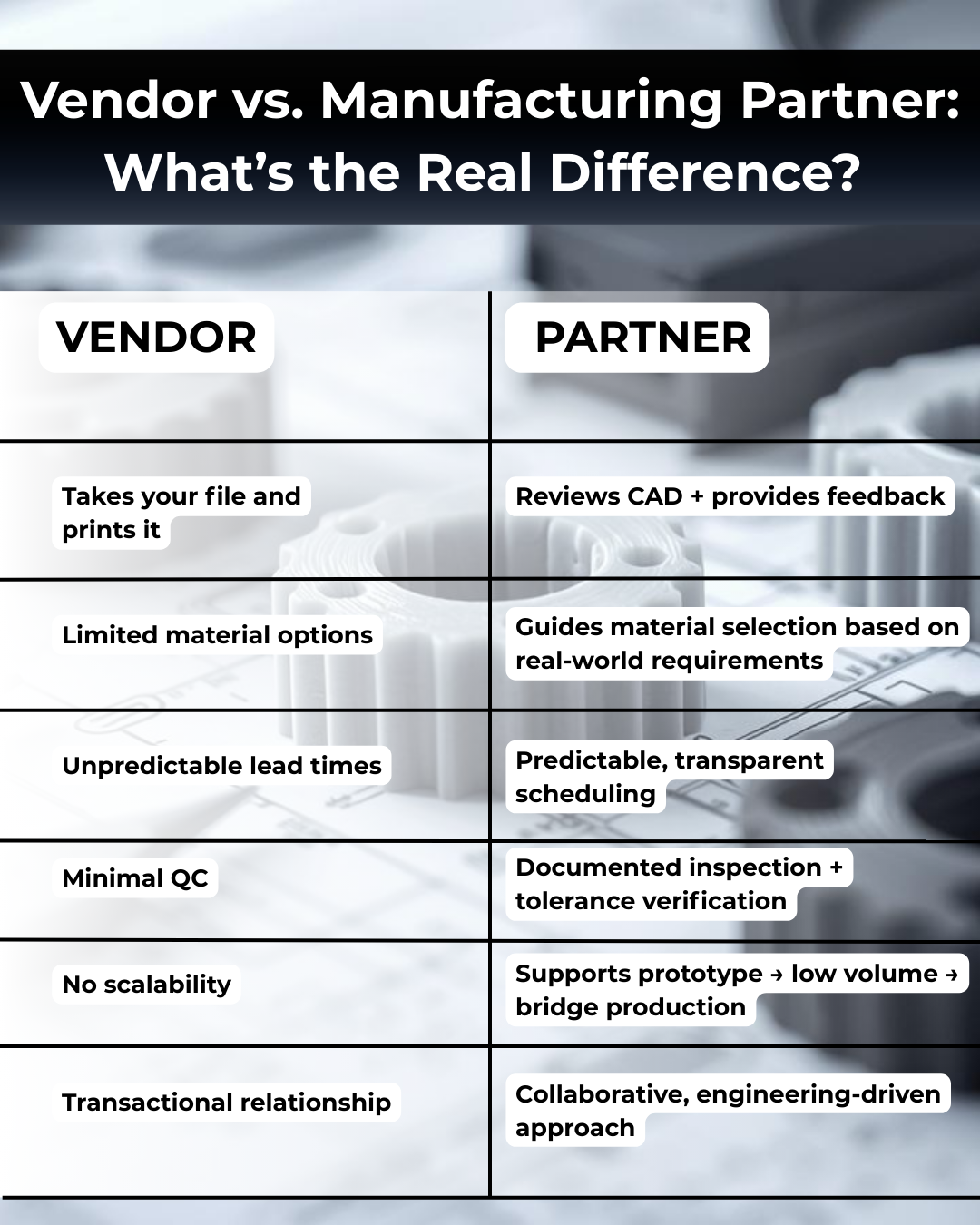

A manufacturer who simply “takes your file and prints it” isn’t a partner—they’re a vendor. Low-volume production often involves evolving designs, tight timelines, and parts that need to function in the real world, not just look good on a screen.

Look for a team that:

Reviews your CAD files before production

Offers design‑for‑manufacturing (DFM) feedback

Helps you avoid unnecessary revisions

This kind of collaboration saves time, reduces risk, and ensures your parts perform as intended.

Learn more about our engineering-driven approach.

Why this matters:

Low‑volume projects often involve unique machines, non‑standard setups, and evolving requirements. Real engineering support helps you avoid trial‑and‑error and get to a working solution faster.

Vendor vs. Partner—why engineering support matters in low‑volume production.

Real‑World Case Study

A customer reached out to us because she couldn’t find hold‑down pins that matched the honeycomb bed on her laser. Every option she found online—including ours—was either too small or too large, and she wasn’t sure whether any of them would work for her setup.

Instead of simply selling her the closest size, our team asked a few clarifying questions:

What is the exact thickness of the honeycomb plate?

What materials do you typically cut?

How thick are those materials?

Would you need extra height to secure different stock types?

These details matter because incorrect pin height or diameter can result in poor clamping force, uneven material hold, or even collisions with the laser head.

What We Discovered

After reviewing her measurements, it became clear that the standard pin sizes wouldn’t work reliably for her machine and material setup. The pins were either too loose to grip properly or too large to fit into the honeycomb grid at all.

The Solution

Using the information she provided, we designed and manufactured a custom pin with the correct height to accommodate both her honeycomb thickness and the range of materials she cuts. The result was a set of hold‑down pins that:

Fit her machine perfectly

Provided consistent clamping pressure

Worked across all her material thicknesses

Eliminated the need for makeshift solutions or oversized pins

The Outcome

The customer received a tailored solution that solved her problem exactly—no compromises, no guesswork. As she put it, “This person went ABOVE and beyond to help me get the sizes I needed.”

What started as a simple “Can you make these for my honeycomb plate?” question turned into a collaborative engineering process that delivered a better, safer, and more reliable setup for her laser workflow.

Full 5‑star review from the customer featured in this case study.

Need a custom solution like this? Contact us.

2. Material Options Should Match Real-World Requirements

Not all materials behave the same—especially in additive manufacturing. Your partner should offer a range of materials that cover:

High‑temperature applications

Impact resistance

Flexibility

Chemical resistance

Lightweight structural needs

A limited material library often means limited solutions.

3. Turnaround Time Isn’t Just About Speed

Fast is good—but predictable is better. Ask potential partners:

What are your typical lead times?

How do you handle urgent requests?

Do you batch jobs or run continuous production?

A reliable partner will give you realistic timelines and stick to them.

4. Quality Control Should Be a Non-Negotiable

Low‑volume doesn’t mean low‑precision. Your partner should have a clear QC process that includes:

Inspection of critical dimensions

Machine calibration routines

Documentation of tolerances

Consistency matters, especially when parts need to fit into larger assemblies.

5. Scalability Helps You Avoid Supplier Switching

Even if you only need a handful of parts today, your needs may grow. A strong partner can support you from prototype to production, including:

Prototyping

Low‑volume production

Bridge manufacturing

Iterative design cycles

This continuity saves time and ensures consistent quality across versions.

6. Red Flags to Watch For

If you encounter any of the following, proceed with caution:

Vague or shifting pricing

No engineering review

Poor communication

Overpromising on tolerances or lead times

A trustworthy partner will be transparent and realistic.

7. How We Approach Low‑Volume Production

At MBS 3D Solutions, we focus on engineering-driven manufacturing. Our team reviews every project for manufacturability, offers material and design guidance, and maintains a quality-first workflow.

Whether you need a handful of prototypes or a short production run, we aim to deliver parts that meet your functional, aesthetic, and performance requirements.

Conclusion

Choosing the right manufacturing partner is about more than machines—it’s about expertise, communication, and reliability. When you evaluate partners through that lens, you’ll find the one who can support your project from concept to completion.

Ready to start your next project? Contact us to get engineering support from day one.